Research Opportunities

Researchers in the Department of Mechanical and Industrial Engineering, in collaboration with industry and government, are successfully pursuing theories and supplying applications in high demand

Current annual support for sponsored research exceeds $3 million.

Support is provided in part by major grants from the National Science Foundation, the Office of Naval Research, the U.S. Department of Energy, the U.S. Department of Defense, the North American Trade Organization and the W. M. Keck Foundation. Close associations with local consulting firms and pharmaceutical, power, chemical, petroleum, and manufacturing companies also provide support and supply a wide variety of state-of-the-art equipment and CAD/CAM systems as well.

Current faculty research areas include: biological systems, computational modeling of complex physical systems, continuum mechanics, design, synthesis and demanufacturing, energetic materials, environmental engineering, fluids, image processing, kinematics and dynamics, micro electro-mechanical systems (MEMS), micro-fluidics, multi-phase flows, nonequilibrium thermodynamics, nanotechnology, nontraditional machining, particulate technologies, plastics, rheology, robotics and system integration, tribology and vibrations of structures.

Articles about Mechanical Engineering Research at NJIT

- Research in High Places, NJIT Alumni Magazine, spring 2004 (PDF)

- A New Phase in Fighting Terrorism, NJIT Alumni Magazine, fall 2003 (PDF)

Industrial and Management Systems Engineering

In the area of industrial and management systems engineering, the Department of Mechanical Engineering has a significant and diverse research program that includes areas such as industrial and operations research, design for manufacturing, quality, assembly and concurrent engineering, robotics, global networking, logistics and simulation issues of small and medium-sized companies, multimedia, environmental and health/safety and medical engineering. Research also is affiliated with these major NJIT research centers: Center for Manufacturing Systems and the Multi-lifecycle Engineering Research Center.

Areas of Research

Granular and Multiphase Flows

The Granular Science Laboratory carries out fundamental and applied research in the field of granular and multiphase flows that is motivated by applications and issues in the solids handling and processing industries (eg., chemicals, agriculture, mining, pharmaceuticals, plastics, materials). A comprehensive range of research activities is performed, including experiments, simulations and analytical modeling. The Lab is engaged in several interdisciplinary projects, among which are several current projects involving faculty from Mechanical Engineering and the Department of Mathematical Sciences.

Mechanics and Materials

Research includes experimental, theoretical, and computational solid mechanics. We work on the development of continuum level descriptions of material behavior under a variety of complex loadings and environments. Examples include shape-memory polymers, polymeric gels, dielectric elastomers, and other exciting areas.

Industrial Engineering, Systems and Operations

Research includes the development of control and scheduling algorithms for the optimization of container terminal operations, global networking and logistics operations for small, medium and large corporations, the impact of telecommuting strategies on traffic flow, engineering system modeling and design tools, distributed virtual laboratory networks between research groups, the R&D of quality systems, quality control and management systems.

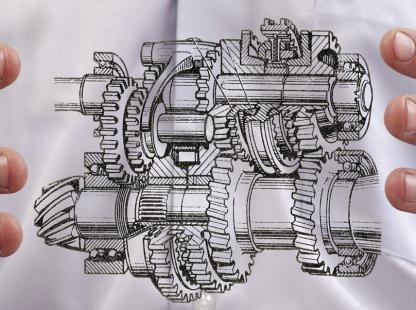

Manufacturing Systems and Mechatronics Engineering

Focus is on robotics, robot cell design, flexible computer-integrated manufacturing, system integration of automation systems, flexible assembly system modeling, integration, implementation, non-contact sensing and inspection, CAD/CAM integration, servo pneumatic positioning and sensor technology.

Concurrent/Simultaneous and Total Lifecycle Engineering

This new research field includes the development of new methods and toolsets for small batch luxury automobile manufacturers (such as Rolls-Royce Motor Cars), and general methods, tools and technologies for design for manufacturing, design for quality manufacturing, and assembly and maintenance systems.

Medical, Environmental, Health and Safety Engineering

Activity in this area is increasing. Main areas include the assessment of the realistic impact of environmental factors on productivity, devices and methods for the prevention of repetitive motion injuries, microrobotic manipulators for human artery cleaning, and new medical devices coupled with simulators and expert systems that can be used for interacting with the human body and other medical applications.

Multimedia, Simulation and Virtual Reality Modeling

Research activities are spread between discrete event and continuous system modeling and simulation and areas such as graphical modeling of workcells, object-oriented simulation coupled with AI, engineering multimedia developments for the study of servopneumatic positioning, multimedia for total quality management and the ISO9001 standard, flexible automation, concurrent engineering and the virtual reality simulation (and rapid prototyping) of complex electromechanical products and their manufacturing/assembly processes.